We met Advenit Makaya, an Advanced Manufacturing Engineer at the European Space Research and Technology Centre of the European Space Agency (ESA). He supports the development of promising advanced materials and processes for space applications and provides support to ESA missions in the field of Materials and Processes. In the past he worked as a Lifing Technologist for Rolls-Royce plc in the United Kingdom, performing structural analysis and lifing assessments of critical parts for large civil aircraft engines.

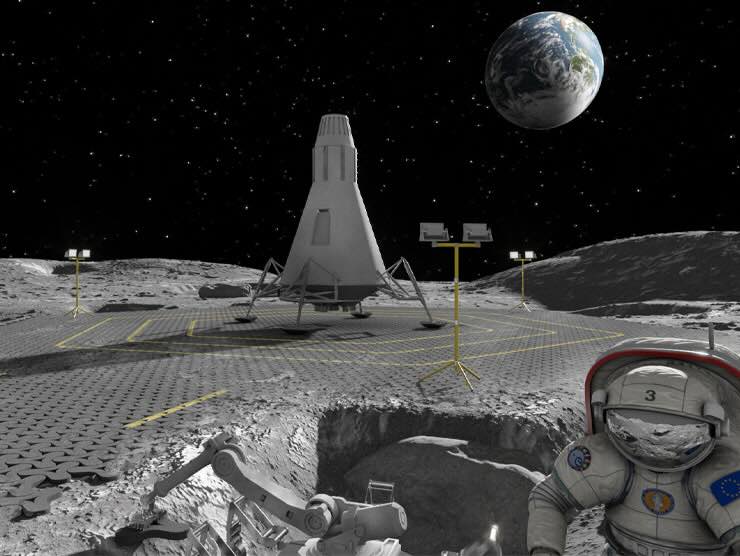

Makaya is also working on ESA’s PAVER project (Paving the road for large area sintering of regolith). The main objective of the PAVER project is to study the feasibility of melting regolith for lunar roadmaking. In particular, the dream is to build a road on which spacecraft can land, eliminating the problem caused by lunar dust. To read the official publication of the research click HERE.

Your dream is to build roads on the Moon through sunlight. What are the characteristics of the paved roads and landing pads on the Moon? Would the material be like a stone slab?

The main objective of the paved areas and roads is to avoid forming big clouds of dust when a lander arrives on the lunar surface, when an ascender takes off from the surface or when a rover rolls on the surface. The dust on the Moon surface has very sharp grains and is also electrostatically charged, so it sticks to every surface and can abrade and damage the equipment that it is in contact with. The astronauts from the Apollo missions identified dust a one of the biggest challenges to lunar exploration. The paved landing pads and roads also have to be strong enough to support the weight of the vehicles landing or rolling on it. They also need to be changed or repaired easily, if they break, so that the pad or road can be used for a long time.

There are difference manufacturing processes considered by different teams, to build landing pads or roads. Some are working on concrete-like materials, by mixing the regolith with various binders. Some other teams are using heat to consolidate or melt the regolith, resulting in a material which is like consolidated sand or like glass. In the case of the activity we did, large scale laser melting (which is a way to represent concentrating the sunlight with a large lens) results in glassy material slabs.

Credits: PAVER consortium/LIQUIFER Systems Group

Could cosmic rays and solar wind degrade the paved road? Also, would the material also resist rocket exhaust?

Cosmic rays and solar wind may have an impact on the paved road material. This is to be assessed at a later stage. However, the material is made of regolith, which has been exposed to cosmic rays and solar winds for a very long time. So, we do not expect that it will be affected in a significant way. The resistance to rocket exhaust or even to a rover rolling on it needs to be assessed by testing. This would be the next step of the development, now that we have obtained a candidate material. As it is a glassy material, we expect that it will be damaged and will need to be repaired or replaced at some point. But exhaust plume testing will help understand if the material meets its primary function, which is to avoid dust cloud formation and also if it can be used a few times before the need to repair/replace them.

Will the production process be automated? What will be the power of sunlight?

The production process on the lunar surface is meant to be automated. In this activity, we used a high power laser of 3kW, but we calculated that the energy output is equivalent to concentrating sunlight with a large lens of about 2.5 square meters. This also takes into account the fact that the solar irradiation on the Moon is higher than on Earth, due to the absence of atmosphere. One idea for automation would be that this lens is mounted on a rover or on a robotic arm, which can be programmed to scan the surface along the pattern corresponding to the design.

What do you love about your job? What project excited you the most?

I really enjoy thinking about innovative ways to meet the objectives of our future space activities, in an open-minded spirit. And then, another exciting part is to translate these innovative solutions into technologies that are practical, still trying to keep an open mind. It is about finding a good balance between imagination and practical considerations. This activity on the paved roads is part of a campaign of activities we did on the topic of “Off-Earth Manufacturing and Construction”, we received a lot of good ideas from industry and universities and some led to interesting achievements, for example in building with regolith, additive manufacturing of polymers and metals in space or even an Internet-of-things concept to track how resources are used in a Moon base. We are launching interesting and promising concepts which will hopefully be a base for how we will conduct long term, sustainable activities on the Moon.

- Cover image: Advenit Makaya (central photo: YouTube); side photo: PAVER consortium/LIQUIFER Systems Group